Struggling with inconsistent vape fills? Incorrect temperatures can ruin your THC distillate and waste money. Getting the heat just right is crucial for quality and efficiency.

The ideal filling temperature[^1] for THC distillate typically ranges from 50°C to 70°C (122°F to 158°F). However, the exact temperature depends heavily on the specific viscosity and terpene profile of your distillate. Always test small batches first.

Finding that perfect temperature sweet spot is key. It ensures your oil flows smoothly for efficient filling without damaging the delicate compounds that define your product's quality. Let's explore why temperature matters so much and what happens when you get it wrong. We'll also look at how timing your capping process is just as important.

What could happen if the filling temperature is too low or too high?

Worried about filling issues? Low temperatures make oil thick and slow, while high heat risks leaks and terpene loss[^2]. Both extremes cost you time and product quality.

Filling THC distillate too cold makes it highly viscous, slowing down production drastically. Filling it too hot can degrade terpenes, altering flavor and effects, and potentially cause immediate leaking due to low viscosity[^3].

Getting the temperature wrong during the filling process can lead to significant problems down the line. It's not just about efficiency; it's about preserving the quality of your final product and avoiding costly mistakes. Let's break down the specific issues caused by temperatures that are either too low or too high.

The Problem with Low Temperatures

When the filling temperature is set too low, the THC distillate becomes very thick, almost like cold honey. Its viscosity increases significantly, making it incredibly difficult for the oil to flow properly through the filling machines. This sluggish movement results in extremely slow filling times. Imagine your production line slowing to a crawl – that's what happens. This inefficiency directly translates to higher labor costs and reduced output. You might need more time, more staff, or even adjustments to your equipment just to get the job done, eating into your profit margins. In my experience, trying to rush thick, cold oil often leads to inconsistent fill levels in cartridges or disposables as well.

The Risks of High Temperatures

Conversely, setting the temperature too high creates a different set of problems. While the oil will flow very easily, perhaps too easily, the heat can be detrimental. Terpenes, the aromatic compounds responsible for the unique scent and flavor profiles of different cannabis strains (and potentially contributing to the entourage effect[^4]), are volatile. Excessive heat can degrade or even destroy these delicate terpenes, leading to a final product with a compromised flavor and aroma, which definitely disappoints end-users. Furthermore, very hot oil becomes extremely thin and runny. This low viscosity increases the risk of leaking, sometimes even before you have a chance to cap the mouthpiece. I've seen situations where oil practically pours out of the hardware because it was heated too much during filling. This not only wastes valuable distillate but also creates a mess and potential hardware failures.

How soon should I cap the mouthpieces after filling the disposables with THC distillate?

Filled your vapes but unsure when to cap them? Waiting too long risks leaks or clogs. Capping immediately might seem safe, but timing is everything for optimal performance.

It's generally recommended to cap mouthpieces within 5 minutes after filling with THC distillate. However, the ideal time varies based on oil viscosity and hardware design. Testing is crucial.

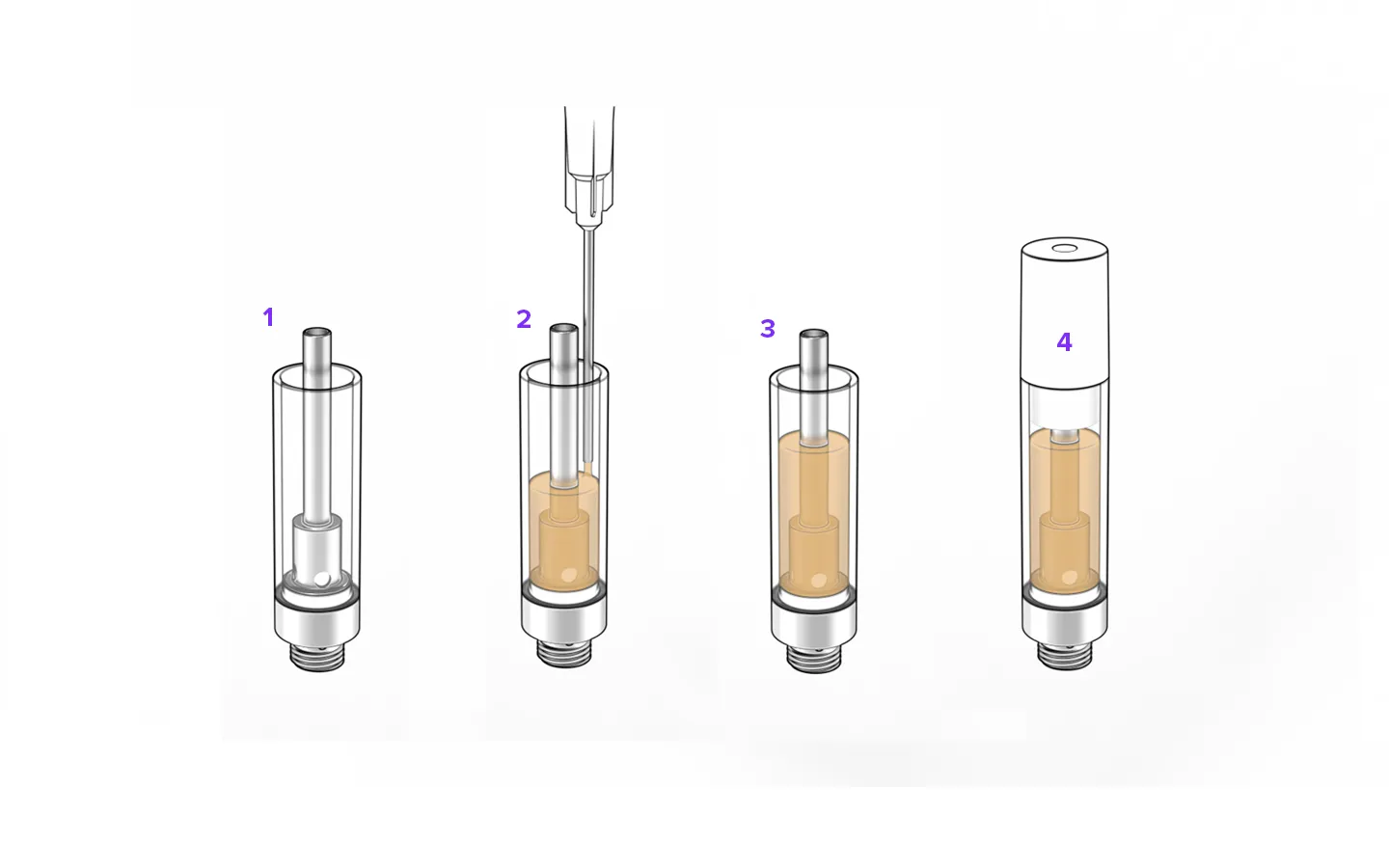

Once the THC distillate is successfully filled into the disposable vape or cartridge reservoir at the correct temperature, the next critical step is capping. The timing of this step is just as important as the filling temperature itself. Sealing the device too early or too late can introduce a new set of problems that affect the final product's performance and user experience. Finding the right window requires careful consideration and testing specific to your oil formulation and the hardware you are using. Let's delve into why this timing matters and how to determine the best capping window for your production.

Finding the Capping Sweet Spot

The general industry advice suggests capping within a 5-minute window after filling. This timeframe is often recommended because it allows the oil sufficient time to settle slightly and begin interacting with the coil or wicking material, but not so long that issues arise from prolonged exposure or temperature changes. However, this is just a guideline. Different oil formulations have vastly different viscosities, even at the same temperature. Thicker oils might need a bit more time to fully settle into the nooks and crannies of the heating core, while thinner oils might need quicker capping to prevent potential leaks, especially if the filling temperature was on the higher side.

The Importance of Testing

Because there's no single "perfect" time that works for every oil and every piece of hardware, testing is absolutely essential before scaling up to mass production. I always advise clients to run trials. For example, take a batch of 100 samples. Fill them all under the same conditions. Then, cap 20 pieces after 3 minutes, another 20 after 4 minutes, 20 after 5 minutes, 20 after 6 minutes, and the final 20 after 7 minutes. Label them clearly and observe their performance over time. Check for leaks immediately after capping and again after 24-48 hours. Also, test them for clogging and initial puff quality[^5]. This comparative testing[^6] will clearly show you the optimal capping window for your specific combination of oil and hardware, helping you avoid widespread issues in your main production run.

Suggested Experimental Groups and Timeline:

| Group | Sample Size | Capping Time (after filling) | Immediate Action (Post-Capping) | 24-48 Hour Action (Post-Capping) |

|---|---|---|---|---|

| 1 | 20 | 3 minutes | Check for leaks and clogging | Check for leaks,clogging and burnt taste |

| 2 | 20 | 4 minutes | Check for leaks and clogging | Check for leaks,clogging and burnt taste |

| 3 | 20 | 5 minutes | Check for leaks and clogging | Check for leaks,clogging and burnt taste |

| 4 | 20 | 6 minutes | Check for leaks and clogging | Check for leaks,clogging and burnt taste |

| 5 | 20 | 7 minutes | Check for leaks and clogging | Check for leaks,clogging and burnt taste |

What potential issues might occur if there is a long delay in capping the mouthpieces after filling THC oil into disposables or cartridges?

Thinking about delaying capping after filling? Be careful. Leaving vape hardware open too long after filling invites trouble like leaks and clogs, frustrating customers and hurting your brand.

Delaying capping significantly increases the risk of leaking, as the oil may seep out before sealing. It also raises the chances of clogging, as the oil can cool improperly or absorb moisture, hindering vapor production.

![]()

Waiting too long to cap your cartridges or disposables after filling them with THC oil isn't just a matter of workflow; it can directly lead to product failures. That time gap between filling and sealing is a vulnerable period[^7] where things can go wrong. Understanding these potential issues highlights why adhering to an optimized capping schedule, determined through testing, is so vital for producing reliable, high-quality vape products. Let's explore the specific problems that can arise from excessive delays.

Increased Risk of Leaking

One of the most common issues caused by delayed capping is leaking. When the hardware remains open, the filled oil is exposed. If the oil is warm and has low viscosity, gravity can simply cause it to seep out through any available opening, particularly around the base or airflow holes, even before the mouthpiece seals the top. Changes in ambient temperature or pressure during the delay can also encourage leakage. As the oil cools, it contracts, but if the capping is delayed significantly, subsequent temperature fluctuations[^8] before sealing can cause expansion and push oil out. We've seen batches where delays in the capping station led to a noticeable percentage of leakers, which is costly and damaging to brand reputation.

Higher Chance of Clogging

Clogging is another major headache linked to delayed capping. When the oil sits exposed in the reservoir for too long before the system is sealed, several things can happen. The oil at the surface can cool down more rapidly than the bulk oil, potentially thickening unevenly around the airway or intake holes of the coil. Furthermore, cannabis oils can be hygroscopic[^9], meaning they can absorb moisture from the ambient air. If the capping is delayed in a humid environment, the absorbed moisture can alter the oil's viscosity and potentially lead to crystallization or separation over time, contributing to clogs. This makes it difficult or impossible for the user to draw vapor, leading to a poor experience and product returns.

The Burnt Taste Dilemma (Capping Too Soon)

While delaying capping is problematic, it's also worth noting that capping too quickly isn't always the answer, especially with very thick oils. If the mouthpiece is pressed on immediately after filling, particularly with highly viscous distillates or resins, the oil might not have enough time to properly saturate the ceramic core or wick before it cools and thickens further. If the heating element isn't fully saturated when the user takes their first puff, they might experience a harsh, burnt taste because the coil is heating dry wick material instead of oil. This underscores why testing different capping times – not too long, but also not necessarily instantaneous – is crucial to find that perfect balance for optimal performance from the very first draw.

[^1]: Discover why filling temperature is crucial in THC distillate production and how it impacts the final product quality. This information is essential for manufacturers.

[^2]: Preventing terpene loss is vital for preserving flavor and effects. Explore this link to learn effective strategies for terpene retention.

[^3]: Viscosity plays a key role in production efficiency. This resource will help you understand its impact on the filling process.

[^4]: The entourage effect explains how different compounds in cannabis work together. Discover more to enhance your cannabis experience.

[^5]: Initial puff quality can impact customer satisfaction and product success. Learn more about its importance and how to measure it.

[^6]: Comparative testing is crucial for identifying the best practices in production. Discover more about its benefits and methodologies.

[^7]: Learning about the vulnerable period in cartridge production can help you implement better practices and ensure product integrity. Discover more in this article.

[^8]: Learn how temperature changes affect oil behavior to improve product design and reliability.

[^9]: Exploring hygroscopic properties can enhance your knowledge of how cannabis oils interact with moisture, affecting quality.